industry knowledge and an excellent team player.

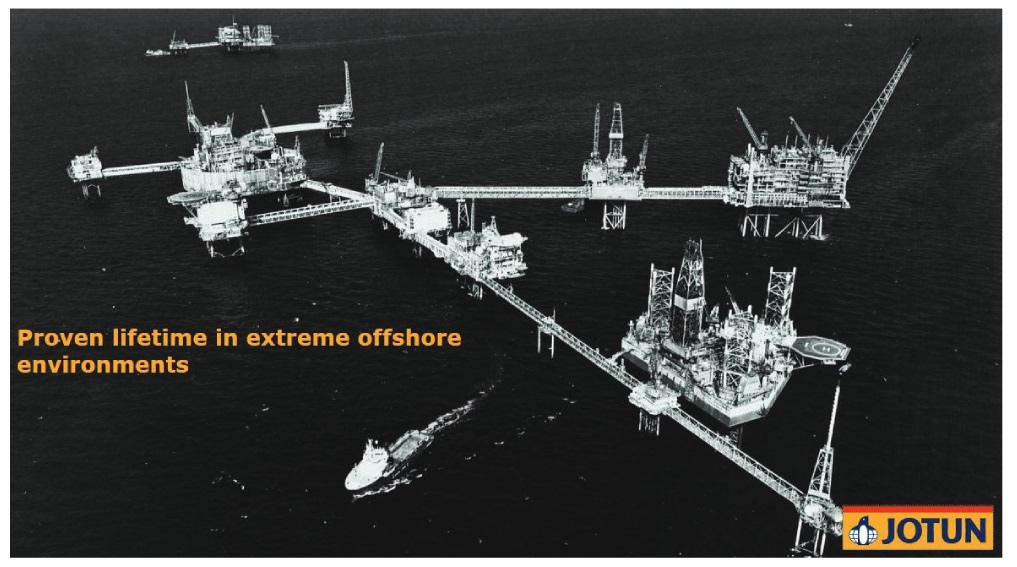

As the offshore wind industry continues to grow and contribute to the global energy transition, innovative and sustainable solutions become increasingly important. One company at the forefront of this movement is Jotun, a leader in the field of coatings and corrosion protection. Baltoflake is a prime example of a product that not only meets the needs of the offshore wind sector but does so with an impressive environmental profile and a proven track record as shown in the recent technical report by DNV showcasing over three decades of excellent performance.

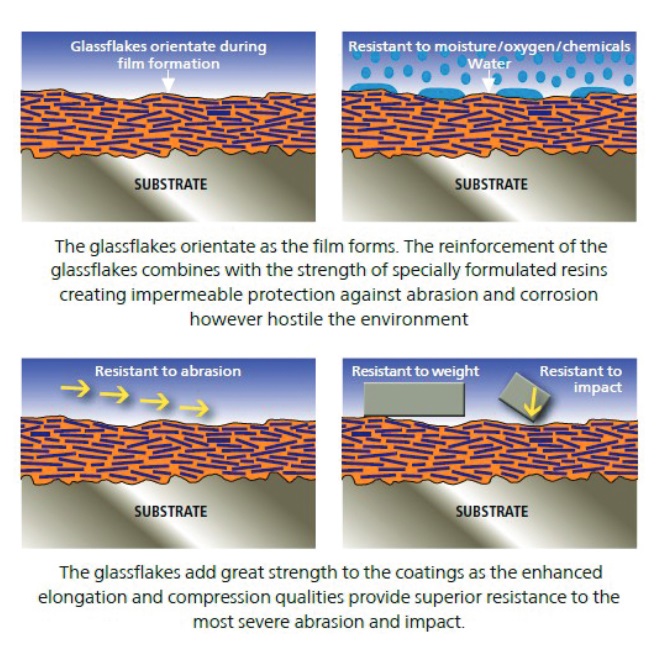

Jotun’s Baltoflake Ecolife is a high-performance, glass-flake reinforced, polyester coating designed specifically for the harsh conditions of offshore environments. It provides excellent corrosion resistance, long-term durability, and superior adhesion, making it an ideal solution for protecting offshore wind turbine structures, subsea installations, and other offshore assets from the damaging effects of saltwater and weathering.

Some of the properties of Baltoflake Ecolife that are beneficial include, Low moisture vapour transmission, High cohesion strength, Chemical resistant, Abrasion resistant, Excellent adhesion to substrate, Excellent water resistance, Compatible with cathodic protection.

One of the main product benefits of Baltoflake Ecolife is its advanced environmental profile. The coating is free from heavy metals and volatile organic compounds (VOCs), which means it has minimal impact on the surrounding ecosystem. This is particularly important in the offshore wind industry, where environmental stewardship is a key factor in project approval and success. By using Baltoflake Ecolife, operators can ensure they are minimizing their environmental footprint while still maintaining high-quality corrosion protection for their assets. Indeed, it is often the case that the greenest option is the longest lasting and with Baltoflake Ecolife that rings true. Given the amount of money, time and crucially energy invested in constructing an offshore asset, making sure it lasts a very long time plays a key role in its green footprint.

The long track record of Baltoflake on the now decommissioned Ekofisk offshore platform is testament to the product’s reliability and effectiveness. For more than three decades, Jotun’s coating protected Ekofisk from the corrosive effects of the North Sea environment. This resulted in an elimination of maintenance costs and the associated benefits.

Baltoflake Ecolife’ s ability to withstand the test of time is a crucial advantage in an industry where asset longevity and return on investment are key considerations. Jotun can provide solution to protect a given area or Structure through its entire lifetime at the lowest possible cost. As the offshore wind sector continues to expand and mature, the need for proven and reliable solutions like Baltoflake Ecolife will only grow more critical.

In conclusion, as per Jay Menon Jotun’s Baltoflake Ecolife offers a sustainable and reliable solution for the offshore wind industry’s corrosion protection needs. With its advanced environmental profile and proven track record at Ekofisk, Baltoflake Ecolife is well-positioned to support the continued growth and success of the offshore wind sector.

Be the first to comment